|

|

|

|||||

|

|||||||

|

|||||||

|

|||||||||||||||||||

|

|||||||||||||||||||

|

DEMKOM KAYNAK OTOMASYON MAKINE SAN. TIC.

robotic@demkom.com Tel/Fax :+90 332 2481213 |

Automation Solutions | Robotic Solutions Home | Demkom | News | Contact Us www.demkom.com | smdemir@demkom.com | info@demkom.com Kaynak,Kaynak Otomasyon,Kaynak Otomasyon Makine,Welding,Welding Automation,Welding Automation Machines,Robot,Robot Cells,Welding Robot,Dairesel Kaynak,Dairesel Kaynak Otomasyon,Circumferential Welding,Rotating Welding,Boy Kaynak,Boy Kaynak Otomasyon,Longitudinal Seamer,Seamer,Kolon Bom, Column Boom,Column Boom System,Tank Cevirici,Rotator,Kendinden Ayarlı Cevirici,Self Aligning Rotator,Maşon,Maşon Kaynak,Vertical welding,Şase kaynak,Tır şase kaynak,Trailer chassis,Trailer chassis welding,Mikser,Mikser kaynak,Mikser Kaynak Otomasyon,Mixer,Mixer Drum,Mixer Drum Welding,Kaynak takip,Kaynak Takip sistemi,Seam Track,Seam Tracking,Osilator,Kaynak Osilator,Oscillator,Welding Oscillator,Lazer,Lazer Takip,Lazer Takip Sistemi,Laser,Laser tracking,Fikstur,Kaynak fikstur,Fixture,Welding fixtures,Special welding fixtures,Fason,Fason Kaynak,Fason Kaynak imalatı,robot fikstur,robot fixtures,Kaynak Muhendisi,Kaynak Muhendislik hizmeti,Welding engineer,Kiris kaynak,Kiris kaynak otomasyon,Gantry,Gantry welding,Gantry welding automation,Plazma,Plazma kesim,Plazma kesim sistemi,Cutting,Cutting system,Plasma cutting,Plasma cutting system,CNC Plasma,CNC Plasma cutting, |

|

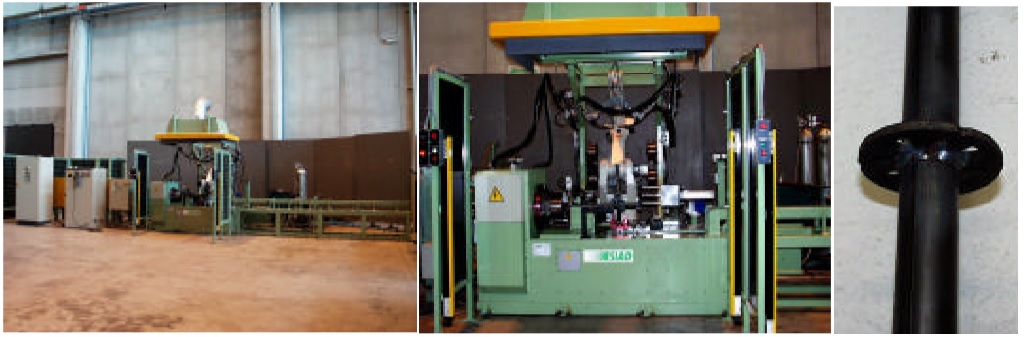

Standard Robotic Applications

Standard Robotic Applications Special Robotic Applications

Special Robotic Applications Example Special Solution 1

Example Special Solution 1