|

|||||||||||||

|

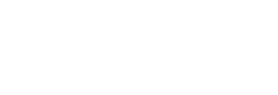

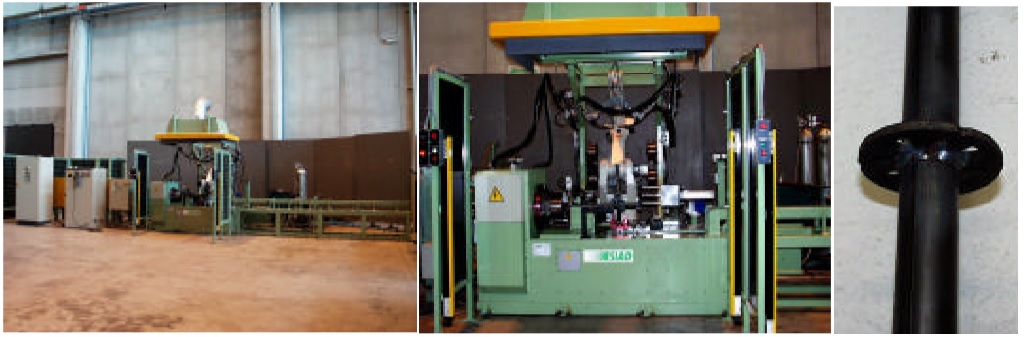

Application : Scaffolding for the building industry with tube and rosettes Features Positioning of max. 8 rosettes in loader. Automized tube feed system, with presetting of rosette number according to type of post. Welding of rosette onto tube from both sides simultaneously with 2-torch system. Welding of joint onto post. Automatic tube unloading. Process data: • Welding process Pulsed MIG with 2 torches • Material Carbon steel

• Robot 6 axes, 20 kg wrist capacity • Peripheral devices Equipment for positioning and clamping rosettes Automatic tube loader,Tube feed system Tool change system

Application : Scaffolding for the building industry Features Robotized unit for automatic loading, welding and unloading of scaffolding. Electro-pneumatic jig for clamping the parts, with robot-controlled release during the welding cycle.

• Welding process Pulsed MIG • Material Carbon steel

• Welding robot 2 robots with 6 axes, 6 kg wrist capacity • Manipulation robot robot with 6 axes, 130 kg wrist capacity • Peripheral devices 3-station positioner 3 with continuous rotation 2 pneumatic transfer systems automatic tube loader • Work stations 2 welding stations 1 loading and unloading station

|

|||||||||||||

|

|

|||||||||||||